One of the main keys for success in the industrial and construction field is the efficient handling of materials. In most cases, the two types of machines, which are used for these operations are wheel loaders and forklifts.

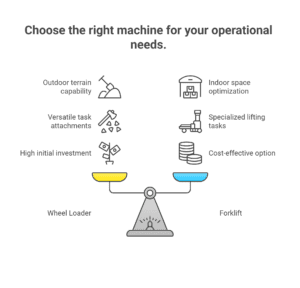

Each of them is specially designed for certain purposes and have their own distinctive features, plus, a perfect combination of pros and cons. By learning about the differences, potential uses, and main properties of such machines, you can not only find the right equipment to meet your needs but also generate profits and minimize your expenses.

Overview: What Are Wheel Loaders and Forklifts?

Wheel Loader

A wheel loader is a powerful tool that carries a front-mounted bucket or forks, which are connected to the hydraulic arms. The machine is simply dedicated to those types of works: loading, unloading, carrying, and moving bulk materials.

The selection of the cargo is what the work process is concerned with—soil, sand, gravel, and construction waste are the most frequent representatives of the group of bulk materials. The sizes of wheel loaders are three—compact, medium, and large—and they are versatile in the fields of construction, agriculture, mining, and quarrying.

Forklift

A forklift is a multi-purpose lifting machine that is mostly used for lifting and moving pallets and materials in a small area where movement is limited. Usually, the area where the machine is located is indoors—in a warehouse, a factory, or a distribution center.

On the basis of the working environment and the specific task, the forklifts can come with different types of constructions, such as a counterbalance, reach trucks, and telehandlers; also, they can be powered by different energy sources, such as electric motors, gas, and diesel engines.

Key Differences Between Wheel Loaders and Forklifts

Advantages of Forklifts

Disadvantages

- The use of more money to buy a vehicle plus the constant maintenance to keep it working well.

- A larger space is required so as not to hurt oneself or others while moving around with the machine.

Pros of Forklifts

- Small and Agile: Perfect for tight, indoor places like a warehouse.

- Accurate Lifting: With the help of a forklift, pallets can be stacked and moved accurately.

- Lower Initial Costs: In most cases, it is more economical to purchase and maintain as compared to wheel loaders.

- Versatile Use: Different industries, such as logistics, manufacturing, and retail, can benefit from a variety of accessories and power sources suitable for them.

- Electric Models: The environment-friendly, low noise, and indoor-use are favorable.

Cons

- It is incapable of performing well on different terrains; it is only suitable for flat and even ground.

- They are manufactured in such a way so that they have small lifting capacity which would be an issue if the load is as heavy as wheel loader’s load only.

- They have very limited functionality for non-lifting operations.

Use Case Comparison: When to Choose Wheel Loader or Forklift

Practical Insight: Load Capacity and Efficiency

Wheel loaders can carry more massive loads, most of the time, thousands of pounds of different types of materials, etc. Their big buckets are an easy way for the operator to quickly and effortlessly lift and load materials and thus the whole process of shoveling and loading gets more efficient, and therefore throughput on the construction, mining, and agricultural fields gets more significant.

In contrast, non-maximum gravity forklifts can be referred to as the ones, which particularly reveal the highest capacity in pinpointing work and at the same time, are usually employed for short repeating tasks, such as moving palletized goods in warehouses, which in turn leads to cost savings for the company.

Maintenance and Operating Costs

- Wheel Loaders: Machine maintenance is basically focused on changing the tires (the wear and tear part in the hard environment), the extraction of the hydraulic system and the engine, and the replacement of the broken parts. Earthmoving vehicles usually consume a large amount of fuel, but the new models are doing so much to raise fuel efficiency, thus saving a large portion of the fuel.

- Forklifts: One of the maintenance tasks that a forklift should regularly undergo is determined by the power type. Forklifts equipped with an electric motor not only consume less energy, which hence reduces the cost but also need less regular maintenance, however, they have the battery replacement problem. In case of a mechanical failure, the gas and diesel forklifts will be the ones that are not only cost-effective due to the low fuel consumption but also highly responsive on the road.

Summary Table: Wheel Loader vs Forklift

Conclusion: Which Is Best in Your Case?

The final say is with you depending on the particular work situation, material type and machine user requirements:

- In the case of an outdoor project that involves a huge volume of materials, rough terrain or very heavy loading, wheel loader is by no means second-best.

- If the problem is that you require quick and easy movement of the goods, and need handling, speed and precision only within the indoor area, then no other machine is as good as a forklift in this case.

- In many cases, you may also have both machines and work on different applications without compromising your processes.

Process of benchmarking each parameter that affects your machine including material characteristics and budget eventually leads you to a product that is very suitable for your purposes and at the same time costs you less which is a result of it performing additional functions.