Let’s be honest. If you’ve been in this game for more than a decade, you know the construction landscape looks a lot different today. Ten or fifteen years ago, the mentality was often “bigger is better.” You brought the biggest iron you could fit on the lowboy, tore up the ground, and fixed the mess later.

Today? That approach doesn’t fly.

We are working in tighter urban infill spaces. Clients are pickier about their existing landscaping. Retaining walls, narrow garden gates, utility mazes buried inches under the surface—these are the daily headaches. I remember a job last summer, trying to prep a patio pad in a backyard accessible only by a 40-inch path between a brick house and an expensive new fence.

Hand-digging it would have blown the labor budget in two days. A skid steer would have torn up the client’s sod beyond repair. That was the moment the true value of a modern mini excavator really clicked for me. It wasn’t just about having a machine; it was about having the right machine.

If you are still relying on rentals that have been beaten to death, or nursing an old machine that leaks hydraulic fluid every time it sees a tough root, it’s time to talk about efficiency. It’s time to talk about what a new mini excavator actually brings to the table, beyond just shiny paint.

We’re going to dive deep into practical applications, what to look for when kicking tires, and why brands focused on fundamentals, like Typhon Machinery, are starting to turn heads on the job site.

The “Squeeze Factor”: Access is Everything

The single biggest efficiency killer on any job is logistics. How long does it take you to stage materials? How long does it take to get the equipment to the actual dirt?

In modern mini excavator construction, the ability to shrink the machine is paramount.

Retractable Tracks act like a “Get Out of Jail Free” Card

If you are shopping for a machine in the 1-ton to 2-ton range, retractable tracks aren’t a luxury feature anymore; they are essential. Being able to suck those tracks in to squeeze through a standard doorway or garden gate, and then hydraulically widen them back out for stability once you’re in the work zone, changes how you bid jobs. You no longer have to factor in fence removal and replacement costs.

The Zero Tail Swing Revolution

I grew up operating older machines where you always had three feet of counterweight swinging out behind the cab. You spent half your mental energy just making sure you didn’t clip a building corner or a laborer with the ass-end of the machine.

Most new mini excavator models prioritize a zero or minimal tail swing design. The house rotates within the footprint of the tracks. The reduction in operator stress is immense. You can park right up against a foundation wall, focus entirely on the bucket, and work faster because you aren’t constantly checking your mirrors in a panic. It sounds like a small thing until you spend eight hours digging next to a client’s brand-new siding.

Beyond the Bucket: The Machine as a Swiss Army Knife

If you think a mini excavator is just for digging holes, you are leaving money on the table. In today’s market, these machines are hydraulic tool carriers.

The efficiency gain comes from never having to leave the cab to switch tasks.

The Mandatory Hydraulic Thumb

In my opinion, buying a new mini excavator without a hydraulic thumb is like trying to do construction work with one hand tied behind your back.

A bucket without a thumb digs dirt. A bucket with a thumb is a grapple. Suddenly, you aren’t just digging a trench for a retaining wall; you are using the same machine to precisely place the heavy armor stone blocks. You are grabbing stubborn tree stumps and shaking the dirt off them before loading them into the truck. You’re neatly stacking demolition debris instead of creating a chaotic pile. The thumb easily doubles the utility of the machine.

Auxiliary Hydraulics: The Lifeblood

When looking at specs, don’t just look at engine horsepower. Look at the auxiliary hydraulic flow rate (gallons per minute). This determines how effectively you can run attachments.

-

Augers: Stop breaking your crews’ backs with two-man post-hole diggers. A mini-ex with an auger drills perfect deck footings in minutes, even in hard clay.

-

Breakers (Hammers): Perfect for selective demolition, breaking up old concrete patios or driveways in tight quarters where a big machine can’t reach.

A truly efficient setup means one machine arrives on a small trailer behind a pickup truck, and it handles the demo, the excavation, the grading, and the material placement. That’s how you maximize profit margins on smaller jobs.

The Operator Factor: Comfort Equals Productivity

This is where the “old school” mentality needs to die a quick death. There’s a lingering idea that being comfortable in the cab makes you soft.

Nonsense. A comfortable operator is a productive operator.

If you are fighting jerky, mechanical lever controls for eight hours a day, sitting on a vinyl slab that feels like concrete, and breathing dust, you are going to be exhausted by 2:00 PM. Your movements get sloppy, you work slower, and mistakes happen.

The Magic of Pilot Controls

When testing a new mini excavator, pay attention to the joysticks. You want hydraulic pilot controls. They offer smooth, low-effort feedback.

Try this test: dial the engine throttle down to about half. Now, try to boom up, swing left, and curl the bucket all at the same time softly. Does the engine choke? Does one function jerk violently while the others stall?

A well-engineered hydraulic system on a new mini excavator should blend those functions smoothly. This allows for the precision grading that separates the pros from the amateurs. You shouldn’t have to fight the machine to get a level trench bottom.

Cab Layout and Visibility

Look at the lines of sight. Can you see the tracks clearly? Is the front window easy to pop open for fresh air and better communication with ground guys? These seem like minor details until you’re living in that box for 40 hours a week.

A Practical Look at Typhon Machinery

This brings us to the current market landscape. You have the legendary, big-name brands that cost an absolute fortune. Then you have the super-cheap imports that you can’t get parts for.

There is a growing middle ground that is getting very interesting for practical contractors. I’ve been keeping an eye on Typhon Machinery.

In this industry, we tend to be skeptical of newer names. But here is the reality: for many small business owners, landscapers, or owner-operators, the ROI just isn’t there on an $80,000 machine that gets used three days a week.

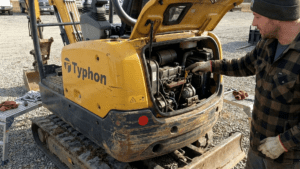

What interests me about the Typhon approach is the focus on the fundamentals. From what I’ve seen, they aren’t trying to sell you a spaceship with heated massaging seats and Bluetooth touchscreens. They seem to be focusing on building reliable iron.

They often utilize proven engine platforms—names you recognize and can get parts for at a local supply store—mated to straightforward hydraulic systems.

If you are looking for a new mini excavator to be a daily workhorse—to dig trenches, load mulch, and drill post holes reliably—you don’t necessarily need the bells and whistles that double the price. You need good breakout force, reliable start-ups, and accessible maintenance points.

For a lot of guys focused on the bottom line, a machine from Typhon Machinery offers that balance of “new machine reliability” and warranty peace of mind, without the massive overhead of the “premium paint tax.”

Maintenance: The Silent Efficiency Killer

The fastest machine in the world has zero efficiency when it’s broken down on a Tuesday morning.

When you buy a new mini excavator, you aren’t just buying the machine; you are buying its maintenance schedule.

Before you sign the papers, open the hoods.

-

Grease Points: Are they accessible? If a grease zerk is buried behind a bunch of hot hydraulic lines, guess what? It’s never going to get greased. And that pin will fail.

-

Daily Checks: Can you check the engine oil, hydraulic fluid level, and coolant without needing tools? If it takes 20 minutes to do the daily pre-trip inspection, guys will skip it. Typhon Machinery and similar practical brands tend to be pretty good about keeping these “mechanic-friendly.”

-

Undercarriage: Look at how the track tension is adjusted. It should be a simple grease cylinder setup. The undercarriage takes the most abuse in mini excavator construction environments. Keep those tracks correctly tensioned and keep the mud shoveled out of the rollers, and you’ll save thousands in premature wear.

Conclusion: Investing in Your Capability

Making the jump to buy a new mini excavator is a significant commitment. It’s scary to sign that finance agreement.

But you have to weigh that cost against the lost efficiency of your current setup. Count the hours wasted waiting on rental deliveries. Count the jobs you turned down because you couldn’t fit your backhoe into the backyard. Count the extra labor hours spent hand-digging around utilities because you didn’t trust your old machine’s hydraulics.

The modern construction site demands precision and speed in tight quarters. A versatile, powerful mini excavator isn’t just a luxury item anymore; it’s the baseline requirement for staying competitive.

Whether you choose a legacy brand or opt for the value proposition offered by a company like Typhon Machinery, the goal is the same: own the machine that lets you do more work, faster, with less headache. Get in the seat, test the hydraulics, double-check the access widths, and get ready to move some dirt.