A dirty or clogged air filter can make your car’s fuel economy poor, make starting the engine more difficult, and consume as much as 10%-20% more fuel. This walkthrough will help you every step of the way with the tools you need, as well as a maintenance schedule and the benefits of regular air filter replacements being covered.

Besides, it is a good practice, not a luxury, if you want to see your machine alive and kicking to have a proper maintenance routine on other mini excavator parts.

Why Change the Engine Air Filter Regularly?

With the mini excavator air cleaners, the air that gets into the engine is dust-and dirt-free, hence the engine can be in a very good condition all the time. The engine will be capable of burning off the fuel-air mixture, even if the filter gets dirty (but less effectively).

- Air Filter is Questionable The air filter is an important component of the air-circulation system that maintains the energy of the engine and transfers power to the wheels of the vehicle. Without it, the engine becomes dirty and may wear out.

- idle The inefficient engine can cause the vehicle to stall in idle mode as it does not produce an even and consistent idling speed. First of all, if the blockage in the filter is not severe, the mixture of fuel and air will still burn, and the engine will work (although not as well).

- Black smoke Black smoke can occur when there is a rich fuel-air mixture because the black smoke is caused by the burning of the carbon from the fuel which is then sent out as the exhaust.”);

- exceeding emissions regulations For instance, if you overload the fuel tank, the fuel goes directly into the carbon canister, saturates it, and causes very serious problems, subjecting you to significant costs for its repair.

Thus, to prevent this It is vital to wash and clean the filtration part after every use of the excavator of about 100 hours and then replace it after a time period of 400 hours or even more frequently in dirty locales.

What Tools and Materials Do You Need?

- A replacement air fillter for your excavator, New brand one

- Screwdriver or wrench that fits the filter housing so that you can open and replace it.

- An air blower for cleaning out the dust or clean cloth to remove the dust

- Safety gloves

- Before you start, first check that you have the following:

- The New Air Filter Here you’d be able to call the customer service contact of AHM and order the filter from us in parallel.

- Essential Tools Basic Tools: No special tools are needed to complete this job. You will require only your hands to turn or push locks according to your mini excavator’s design.

How to Change the Air Filter Step by Step?

Step 1: Prepare Your Excavator

- Put your mini excavator on the ground. Make sure its flat and stable.

- Make sure the engine of the car is switched off and take the key out. Let the engine cool down so that there is no chance of injuries or burns.

Step 2: Locate the Air Filter

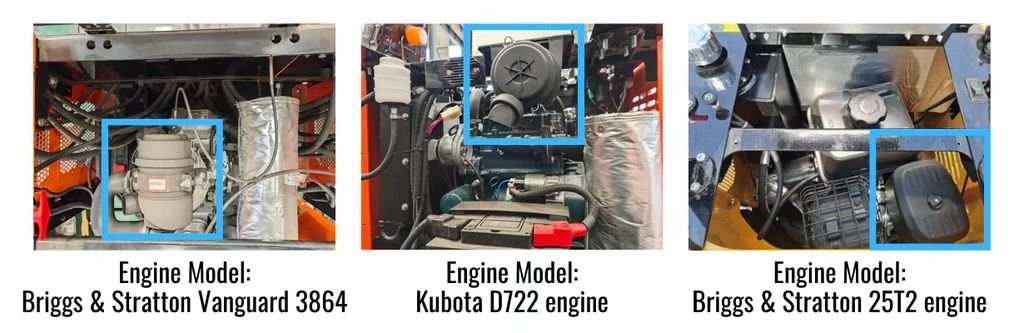

Open your seat to get entry to the compartment of your engine. The location of the filter will be different based on your car model:

HT-12/AX-12 Mini Excavator:

Features a 13.5 HP Briggs & Stratton (B&S) engine, specifically the Briggs & Stratton 25T2 model.

AX-12B Mini Excavator:

Also equipped with a 13.5 HP B&S Engine, utilising the same Briggs & Stratton 25T2 Engine.

NW-12 Mini Excavator:

Comes with a 13.5 HP B&S Engine, again using the Briggs & Stratton 25T2 Engine.

HT-12C/AX-12C Mini Excavator:

This model features a 13.5 HP B&S Engine with an enclosed cab, powered by the Briggs & Stratton 25T2 Engine.

HT-15/AX-15 Mini Excavator:

Equipped with a slightly more powerful 13.8 HP Kubota Engine, specifically the Kubota D722 model.

HT-16/AX-16 Mini Excavator:

This model has a 23 HP B&S Engine, featuring the Briggs & Stratton Vanguard 3864 Engine.

Step 3: Remove the Old Air Filter

-

for Briggs & Stratton 25T2 Engine The lid must be turned counterclockwise to remove it.

-

for Kubota D722 Engine Or Briggs & Stratton Vanguard 3864 Engine: Press the lock to open the lid. Take off the old air filter by pulling it carefully out.

Step 4: Install the New Air Filter

First of all, take the new air filter in your hand and then push it into the slot that the previous filter was in. Check that the filter has been put in the right way. Now, in the same way exactly, close the door:

- for the Briggs & Stratton 25T2 engine cover, turn it in a clockwise direction or To lock it.

- If you have Kubota D722 engine put the lock back into the place where it was and it will also work for Briggs & Stratton Vanguard 3864 Engine.

Step 5: Test the Excavator

Get the engine running, then wait for a couple of minutes for it to warm up properly. Check the engine to make sure it is properly running and that it is free from any strange sounds or odors. If the result is satisfactory, there is no problem!

ConclusionFor the best performance of the micro-excavator, change the air filter every 400 hours. However, in the dusty environment, the replacement may be needed to be more frequent. This simple yet crucial upkeep will prevent engine issues, reduce fuel expenses, and prolong the life of the machine.

Be sure to employ only genuine replacement parts and adhere to the manufacturer’s directives for you to get the most of your equipment. At AHM we have mini-excavators plus full customer support so you can be sure to make the most of your equipment. In case you have any questions do not hesitate to contact our support team via email or telephone.