The evolvement of the excavator has been stunning, notably, in the last ten years. The new models of the excavators are now armed with systems of high standards that not only extend but also improve their operationalizations which, in turn, makes them to be the most efficient and versatile machines in the whole history of the excavators.

One of the most prominent features is the onboard telematics equipment that enables wireless tracking of machine state and partner. The telematics-wireless instruments collect the everyday reports on the fuel they burn, on engines’ good health, i.e., keeping the standards, and on the number of hours machine operations, thus making workers and fleet managers eager to get useful feedback from maintenance and usage.

The companies, for instance, in their efforts to prevent breakdown events, may use the performance data look for way of potential faults and thus schedule necessary maintenance before this unluck happens.

In addition to this, the invention of artificial intelligence in the excavators has revolutionized the era of manual labor in commanding the machines. A great number of new products are designed in such a way that they have partial self-governed features which, however, may need human assistance to some extent.

This does not only cut down the risk of human mistake but also extends the time by the operator doing other important works on the same project. For instance, some of the newly introduced excavators are able to get their tools automatically deepened or elevated at a certain angle as per the set parameters thus allowing work such as trenching and grading to be done accurately. Such perfectness as in the case of complex job sites is only attained at this level of automation.

Key Takeaways

- Comprehending modern excavator technologies:

- Success of the operations is greatly improved by the integration of advanced technology in the excavators that besides the telematics also includes the GPS, and this is what leads to better accuracy and efficiency.

- Boosting productivity through the inventive features of an excavator:

- The implementation of features like automatic grade control and the use of hydraulic systems has led to a great increase in productivity plus the welfare of the operator is also taken care of as he is not subjected to fatigue.

- Making use of the newly designed excavators to improve safety:

- The change in the models of excavators today has brought with it the factors of improved visibility, operator assist systems, and the use of intelligent safety devices that hinder accidents and injuries altogether.

- Discovering the benefits of retrofitting with enhanced excavator attachments:

- Among the revamped attachments are the tilt rotators and quick couplers that provide an application of multiple usages in a variety of works and at the same time becoming time efficient.

- Enhancing the effectiveness of the excavator through well-thought-out designs:

- Some of the revolutionary designs in the category of excavators are compact and hybrid and are targeted at leading the way in efficiency maximization as well as in the reduction of fuel consumption.

Improving Productivity with Advanced Excavator Features

Fast-working functionalities are the main reasons why an excavator of the latest design would come installed with numerous valuable features. One of the examples of a remarkable development may be the high-performance hydraulic systems that are constructed and designed to give better power and longer life to the machines. According to the calculation, these facilities shorten the cycle time, and hence operators can do their jobs faster without a loss to performance.

For instance, the variable flow hydraulics-equipped excavator can regulate the flow rate as per the specific operation, thus, achieving proper utilization of energy and making the machine work more efficient in the global manner. This feature is very demanded in places where time is very important such as urban constructions or any other emergency cases.

The creativity in control systems is another feature that raises the level of productivity. The majority of touch-screen controls built into modern excavators come equipped with easy-to-use machine operation skills. Inaugurating such operability usually means setting up predetermined routines that skillfully adjust the controls to work along with the operator’s habits or specific task conditions.

A further point is that features such as automatic bucket return and one-touch digging can also be considered to be simplifying activities, thus decreasing the training time needed for new workers and, consequently, raising the job site efficiency extensively.

These efficient features working together not only accelerate the process of transition from one project to another but also make it possible to realize substantial cost savings as the money saved on diesel and machine maintenance is utilized elsewhere.

Enhancing Safety with the Newest Excavator Models

Safety, above all, has always been a major issue dealt with in construction and digging works, and the latest models of the excavator have been conceived from this point of view. To ensure the safety of operators as well as those on the ground, manufacturers have loaded the machines with a plethora of safety features.

One exemplary safety feature is the adoption of 360-degree visibility systems, which combine cameras and sensors to deliver to the operators the complete view of their environment. Such technology tremendously minimizes blind spots, hence, employees can drive tight, narrow, and congested job sites with higher confidence and safety by being aware of the threats around them.

Besides the visibility improvement, many new excavators are rigged with an advanced stability control system. The system keeps track of the machine’s center of gravity and the hydraulic functions and adjusts them in such a way that the function of the tipping or instability is prevented.

So, in the case of working on terrain that is not level or close to edges, these systems can, without the assistance of a person, change the machine’s position to keep it at a point of equilibrium.

Also, as a complement, features such as an emergency shut-off switch and operator presence detection system, which keep machines from being active if they are under threat, add a bit more to the site safety protocols.

Exploring the Benefits of Upgraded Excavator Attachments

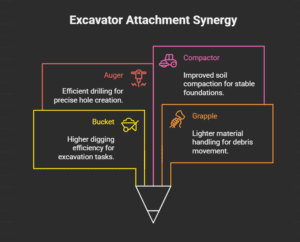

Among the numerous equipment that are often utilized in the construction field, one of the most significant is without a doubt the available excavator attachments. Moreover, this is even more true after the most recent developments made in this sector. One of the cases can be the modernized auxiliary equipment consisting of the hydraulic thumbs, grapples, and special buckets which allow the machines to cover the widest possible range of works in an efficient manner.

Let us now consider how the hydraulic thumb can contribute to the mentioned versatility of the machine. In fact, a hydraulic thumb attachment is one of the accessories that will turn an excavator into a cleaner user, a user that is able to pick up and move the material more easily. Basically, it is releasing productivity growth while at the same time lowering the demand for the number of machines on the site.

Besides, technological progress in attachment technology has resulted in the creation of fast couplers that make it easy to change attachments quickly. The pre-eminence of this feature in the operator’s work is that he is able to switch between different attachments within a short span of time, which is a great advantage to the project.

For instance, it is only a matter of seconds before the operator is switching over from a digging bucket to a grading blade without the need for any extra tools or help. This is a great achievement indeed! The point here is that such a situation is very helpful in projects where it is required to do several works one after another as it facilitates operations and makes it possible to keep a constant pace of the project.

Maximizing Efficiency with Innovative Excavator Designs

The adoption of modern excavators has gone under profound reforms in terms of the aim of the reform being to maximize the efficiency and performance. The essence of the reformation is based on the embracing of the reduced scale/mini/compact models while the value of the output remains a topic of discussion, along with the application of functions, the energy put by the machine not being surrendered, and more importantly, its maneuverability in restricted and tight urban places.

Many times, these machines incorporate the so-called zero-tail swing models which empower them obtaining operations near walls and other sorts of barriers, keeping at the same time distances from the protection.

Another method for the company to tackle fuel consumption issues and enhance designs is through the use of lightweight materials and efficient engines. Some of the advanced composite materials used for chassis and bodywork have practically been proposed for the different areas that make up the vehicle, and this help in keeping their density at a minimum.

The total weight of the vehicle can thereby be significantly lighter while its resistance quality remains intact, which in turn leads to the lowering of the fuel consumed during the operation.

Apart from that, there are certain manufacturers that have already incorporated hybrid models that combine the traditional diesel-powered engine with electric power sources. This combination has led to an enormous drop in hermitage emissions and operating costs. Besides this, the trend towards sustainability in the construction sector is not only making an important contribution to the environment but is also an industry-wide move towards greener construction practices.

Choosing the Right Excavator for Your Job Site Needs

Deciding on which excavator is most suitable for a specific job site your project can be done by first assessing the project scope, the type of terrain, and considering if any attachments are needed.

The basis for a wise decision will be nothing else than really understanding the project’s requirements. To expound, earth moving, project-related heavy will be brewed by the huge ones and they, on their part, will ask for full-sized excavator to take ussembling off and digging lowering if necessary. On the contrary, installing lighting in less roomy places will go better if compact rigs which are light on movement and strength are used.

The category of attachable parts news deserves to be mentioned as the secondary major factor connected with the subject. Since the case is of the characteristics of rigid-object materials of which we want to break, hammers will be irreplaceable aid tools.

And while it is quite an advantage the versatility of an excavator supplies with regarding its fusion with multiple attachments, still this won’t affect much on an individual job site. Besides that, we can hardly leave out consideration of the user-friendliness aspect of the operator’s comfort and ease of use; well-equipped with ergonomic controls and a luxury cabin, the machine can energize long working hours through operator fatigue reduction.

Training and Maintenance for the Latest Excavator Models

Undeniable as technology advances in excavators, following all teachings and maintenance prescriptions become crucial in getting the best performance out of the machine as well as in prolonging its life span. Knowledge of the latest features and controls is very important for operators if they are to get modern machines to perform at their full potential.

One of such manufacturers circles is where enrollments in easy-to-hard operation classes and use of automated features are provided. The commitment of resources to extensive skill-building of operators is not only an enabler of the safety culture but also a major promoter of such. Equipment has also undergone transformation with the brand new technology in the installation of maintenance schedules.

Standard regulations for maintenance are necessary for the machines to operate without any hitch and also prevent the occurrence of problems that the operators cannot foresee.

A telematics system is instrumental in this by giving the necessary notifications for the appointments of maintenance checks based on the current data. The notifications could come through the consoles where the operators are situated, and they could be about oil change, filter replacement, or any other removal tasks made for the convenience of the operators.

This positive attitude towards maintenance eventually leads to the excavators’ long life exploit while at the same time suffocating the occurrence of machine failures.

Future Trends in Excavator Technology and Industry Impact

There are a lot of trends that in the future will be leading the way for excavator technology development and the construction industry impact. One of them is the progressively deeper fusion of artificial intelligence (AI) with the operations of an excavator.

AI-powered solutions can collect data from numerous sources, assess it to find the best way to achieve performance, and, importantly, they can even automatically reconfigure any given setting as would be required by a recent ground or weather condition. Imagine if each of the machines on a wide array of different worksites could simply ‘morph’ into just the one perfect machine due to its versatility brought by such a level of adaptation!

Their fossil footprints will surely be slashed remarkably in a yet unprecedentedly easy way. Moreover, the issue of environment conservation will again play a pivotal part as the ‘motivator’ for the next major breakthrough in electorate technologies for the heavy-duty machinery industry such as the New World of House Number 1.

We can witness the transition from dirt, noise, and heavy machinery to smooth, quiet, and eco-friendly machines once the wagon makers put up their electrifying advertisement to the world about the electric or hybrid variants that will tackle pollution without compromising power and productivity!

This environmental upheaval will not remain confined in machines only as the demand for more sustainable practices will somewhat change the entire construction industry in the way projects will be conceived and executed.

To summarize, with rapid progress in excavator technology leading to the emergence of various advancements, a comprehensive understanding of them becomes necessary for industry professionals looking for the improvement of their productivity and efficiency on-site.

The embracement of cutting-edge features, groundbreaking concepts, and eco-friendly lifestyles holders will without a doubt etch the outline of future excavation work for a long time coming.