The Kubota mini excavator, although small in size, is a robust and versatile machine whose popularity has skyrocketed in the last couple of years in the construction and landscaping sectors.

Being a dependable and all-around-use machine, it can be your go-to device for jobs like digging, trenching, lifting, or leveling. A Japanese company named Kubota, with a long legacy of quality engineering, has made six mini excavators in total to cover the need of the customers in different ways and get them used in various applications.

The manufacturers of these machines have a special place in their heart for this kind of operation i.e. working in tight and narrow places where the big machines are at a standstill.

Power and control, as are desired, are provided through the hydraulic system, which happens to be one out of several great features associated with Kubota mini excavators.

The said hydraulic system makes the parts of the machine, that is, the boom, the arm, and the bucket, work evenly and therefore the operators are able to make very accurate and precise movements.

Not only are they efficient in that respect, but the minis are also outfitted with some other high-tech performance gadgets such as variable-speed control and automatic idle functions. Besides providing contractors and operators with the ease of work, these programs account for less fuel consumption and so they become a cost-effective option.

Key Takeaways

- Kubota Mini Excavator is a highly efficient and versatile machine that can be used for a wide range of construction projects.

- The proper operation and maintenance of the Kubota Mini Excavator are of utmost importance to its longevity and performance.

- Simply by the use of attachments, you are able to amplify the function of the Kubota Mini Excavator to suit the varied needs of a worksite and thus save time.

- In order to avert mishaps and injuries, safety considerations are of first priority in the case of the Kubota Mini Excavator.

- Applying suitable tips for working with a Kubota Mini Excavator will not only energize you but also guarantee the accomplishment of your target in the construction site.

Proper Kubota Mini Excavator Operation and Maintenance

It is indeed a combination of smartness, understanding, and safety that makes operating a Kubota mini excavator successful. Operators should engage in a thorough pre-operation check before starting the machine. Among the items under inspection should be checking fluid levels, inspecting tracks for wear, and safety feature functionality.

The operator can also enjoy more comfort and control through the correct adjustment of the seat and settings which suit the physical and mental attributes of the operator.

Getting to know the machine’s controls should be the top priority of the operators; they should familiarize themselves with every implement and button function to achieve maximum efficiency.

Preventive maintenance is just as important in Kubota mini excavator’s health and wellness. Regular servicing such as oil and filters changing and tracks adjustment should be carried out following the manufacturer’s instructions. A machine should also be kept neat from dirt and other residues which gradually clog up the machine’s nooks and crannies resulting in malfunctioning.

Operators who care about the hydraulic system they are working with must check the situation of the hoses through which the fluid is running and also be on the lookout for signs of leaks in the system. Operators who strictly follow a maintenance schedule will not only save themselves from having to fork out money for repairs but also the valuable time when the machine is unavailable for use.

Utilizing Attachments for Versatility and Efficiency

A feature that significantly sets Kubota mini excavators ahead of their competitors is the compatibility they have with such a vast variety of different attachments. The most usual attachments cover various sizes of buckets, augers for drilling holes, grapples for picking up materials, and hydraulic hammers for breaking concrete. Each of these additions makes a certain function possible thereby making operators the ability to complete different tasks without necessarily having multiple machines.

Trenching bucket, for example, can make trench digging for utility or drainage system a walk in the park. No one can really deny the great work one is able to accomplish using attachments.

To illustrate this, when an auger is set on, a Kubota mini excavator can carry out the drilling task for fence posts or foundation piers in a quick fashion, thus, time is saved as opposed to when it is done by hand. Similarly, a hydraulic thumb attachment when teamed up with a standard bucket will give it the functions of a grabbing and moving tool of irregular shaped objects.

In this manner, not only is time utilized in the best way, but also labor costs are reduced as a result of lesser requirement of additional equipment or manual labor.

Safety Considerations when Operating the Kubota Mini Excavator

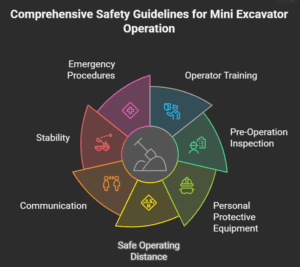

Precisely, safety concerns come first to mind whenever we talk about heavy machinery such as the Kubota mini excavator. A lead character who is naturally responsible to observe the requirements for the scene is the operator himself. A day at work is therefore a good time to establish a safe zone by setting marked lines for the area and making sure that people are far enough away from it.

Besides that, operators in different settings should undergo training to be able to identify hazards such as low power lines, or unstable grounds which might cause accidents during the time of work.

Operators can also rely heavily on the help of Personal Protective Equipment (PPE) in the process of ensuring their safety. A hard hat, safety goggles, gloves, and steel-toed boots are the four essential items that everyone on a construction site must wear.

Moreover, operators ought to make themselves acquainted with the safety features of the machine, like emergency shut-off switches and alarms. Along with this, the practice of having regular safety training sessions can be a very effective method to maintain the level of the safest practices and also to make sure that all the personnel who are either involved in operating the machine or working near it have access to information regarding the potential dangers.

Tips for Efficient Digging and Trenching with the Kubota Mini Excavator

Digging and trenching efficiently with a Kubota mini excavator are not only dependent on the skill of a person but also on the understanding of the machine that is in use. One such procedure would be that in order to deepen the digging to the maximum without losing the stability the user could engage the boom and the bucket of the machine along with its arm.

Firstly, before any digging operation, the operator should locate the excavator on stable ground and use the tracks to create a solid base around. At the same time, this method also gives personnel a warning about the risk of the vehicle losing stability due a tipping over or other.

A further fundamental factor in efficient digging should be that individuals understand the differences in soil conditions. The nature of each different kinds of soil (clay, sand, or rocky land) requires various methods.

For example, while working in clay soil, it will be wise to take a less wide bucket in order to be able to penetrate the compacted layers more efficiently. Therefore, it could be that excavators can dig faster with a larger bucket due to the loose nature of the soil when dealing with sandy soils. As a result, they can be more productive by relying on the machine’s capabilities and adjusting their methods based on the soil conditions.

Maximizing Productivity with the Kubota Mini Excavator in Various Construction Projects

The Kubota mini excavator’s adaptability makes it the most significant contributor to any construction project, from residential landscaping to commercial site preparation. Essentially, this machine will boost the productivity of the projects that it is part of, if it is used correctly.

As an example, in the case of residential undertakings as in the renovations of backyards or the set up of pools, the mini excavator’s diminutive size permits it to go through restricted areas and be still able to provide satisfactory performance.

For example, in the case of larger commercial projects in which road construction or utility installation is involved, the Kubota mini-excavator can be combined with other heavy equipment and put to work to make the activities more efficient.

By assigning labor between machines that e.g. mini-excavators are being used for carrying out the digging while the rest of the equipment like the loaders are being used for material transport the result the contractors get is of being able to gauge better their moving operations in conjunction with time saving significantly reducing their project workflow.

Part of such preparation could be done through an advanced mode of scheduling which may allow for tracks of efficient equipment utilization over a project period of time.

Advanced Techniques for Precision and Accuracy with the Kubota Mini Excavator

Most of the time to get the precision and accuracy with a Kubota mini excavator you will have to employ advanced techniques which not just the basic operation skills can do. The first can be a demonstration of the machine’s hydraulic controls wherein delicate tasks such as grading or adjustment of the height are performed.

The operator’s technique of feathering the controls i.e. bringing in the small adjustments for boom and arm movements to get smoother transitions as well as more precise results can be leveraged.

One more advanced approach is the application of either laser grading systems or GPS technology that is embedded into the excavator’s controls. Elevation changes are monitored by these systems and operators can keep the grades even throughout the whole area. Operators by adopting these techniques can elevate their level of accuracy as they do tasks such as site preparation or drainage installation, which is the reason construction projects will have better results.

Troubleshooting and Common Issues with the Kubota Mini Excavator: How to Address Them

In spite of the fact that they are dependable, Kubota mini excavators can face some typical problems which operators need to be able to solve right away. One of the problems that happen very often is the hydraulic system failure which symptoms can be very slow or unresponsive movements of the boom or arm.

So the first thing the operator should do is to make sure that the fluid levels are good and that the hoses are checked for leakage or damage. If after making sure the fluid levels are okay the problem still continues, then it is advisable to check the troubleshooting steps in the operator’s manual or seek the assistance of a qualified technician.

Another common issue is that of wear or misalignment of the tracks that can result in safety and performance problems during the running of the machine. They should check the tracks for signs of wear and any damage and also make sure that the proper tension is maintained according to the manufacturer’s specifications.

In case the tracks are out of alignment or too worn, it may be necessary to adjust them or even change them to regain their optimum functioning. They will at most times be in a position to prevent breakdowns by timely addressing the issues thus, operators will enjoy productive Kubota mini excavators with little or no downtime.