Mini excavator is another term for a 2 ton digger which is a small and multi-purpose heavy machinery that can be used for a wide range of construction and landscaping jobs. Generally, 2 ton machines that weigh about 2,000 kilograms are liked most for their ability to move around comfortably in small areas and at the same time, deliver great digging power.

On account of its 2 ton digger design, it handles these jobs as digging a trench, grading the surface, and demolishing a structure the incredible way one would expect. Acting out various projects at home or in commercial settings, the hydraulic arm and bucket which are standard for these diggers may reach a depth of 3 meters.

A 2-ton digger is loaded with several features that allow it to operate at its maximum power. A rotating cab which enables the user to have a full view and access the location from any angle is one of these features.

It is found that this movement capacity is of great help when trying to operate in very small spaces where larger and traditional excavators are having a hard time. Moreover, quite a few models come in with tracks that can be adjusted for width and length in order to suit the terrain and thus, offer safe footing on a rugged area.

One more example that the 2-ton digger can be very versatile is the fact that it can change over in the middle of different attachments, for example, of car, breaker, and grapple, consequently, the 2-ton digger is a handy tool for contractors as well as for landscapers.

Key Takeaways

- A 2 tonne digger is a multi-purpose machine that can be used for dirt works as well as building works.

- A regular schedule of maintenance and the proper use of the machine are the two main factors that determine the machine’s working time and performance.

- Notably, the selection of the right attachments can increase a digger’s range of applications as well as its value.

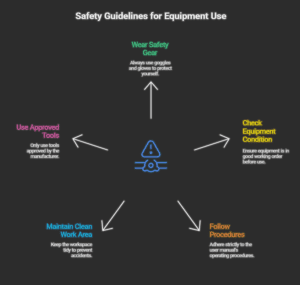

- For the safe and efficient working of the machine, a worker must be trained properly and a safety guideline must be implemented.

- Making fuel consumption as efficient as possible can save big amounts of money in the long run.

Proper Maintenance and Care for Optimal Performance

First of all, the regular maintenance is a must to a 2-ton digger to function at its best performance. This should mainly consist of hydraulic fluids as well as engine oil, and coolant level checks. Hydraulic systems, in general, are very fragile; if there is a leak or the fluid level is low, the performance may be lowered and at the worst, a total breakdown may occur.

The employees who are working there have to check the hoses and connectors for safety and protective codes, as these two parts are the main ones to help the machine.

Furthermore, the wheels of the vehicle must be cleaned regularly to stop the dirt and other particles from gathering, and thus causing the tracks and the rollers to wear out earlier than they normally would.

Another issue about upkeep is involved in the checking and the changing of filters. The air filters ought to be frequently checked to ascertain that the engine is getting the clean air it needs for the best combustion process. Likewise, fuel filters should be replaced as per the manufacturer’s recommendation to avoid impurities from entering the fuel system.

The performance of the digger will be upgraded not only if the maintenance is regularly scheduled but also if the safety of the personnel is taken into consideration, which will then lower the possibility of a machine failure during operation.

Maintenance can be planned using software as well and various events which may require the operator to respond to an issue can then be identified well ahead of schedule.

Choosing the Right Attachments for Versatility

One of the main things that really allow a 2 ton digger to be a versatile machine is the wide range of attachments that the matt can take, which automatically increases its functions.

For example, with the help of a hydraulics finger the digger will turn into a giant crane that can lift heavy items like boulders or ugly wastes! Besides, this add-on can enable the user to grip and move the nonstandard-shaped objects with micrometric handling that will be vast on a construction site where re-organizing materials is a big part of the work.

One more accessory that is much in demand is the earth drill which is the best tool for making holes in the ground to insert fence poles or plant trees. Depending on the size of the hole to be dug, we have earth drills of different sizes.

Also, for instance, a bigger earth drill may be the first choice if the foundation is planned to be very deep, while a relatively small one will be enough for the landscape.

Furthermore, using a tool like a breaker will gradually diminish the resistance of the digger against hard materials allowing it to destroy easily even concretized or tarmac surfaces.

Operators can, thus, achieve the maximum performance for their 2-ton diggers by first zeroing in on the appropriate attachments and then deploying them for the target task thus turning the machine into the multipurpose one.

Tips for Safe and Efficient Operation

Operating a 2 ton digger needs not just the mastery of the technical part but also the operators’ knowledge of safety protocols to sidestep accidents on the location.

A very simple but safety rule, however, is that the pre-operation inspection must be done every time. Besides searching for any damage that is visible, part of the inspection should be a check for safety features and fluid levels.

Operators should also familiarize themselves with the machine’s controls and functions so that they can react promptly in case of an emergency. Besides this, a communication link between the operator and the ground crew is very important during maneuver. Besides hand signals and two-way radios, there are also other instruction tools which you can use for better coordination and safety.

A worker must, for instance, be vigilant to the exposed wires overhead (if any) and the fellow workers in the vicinity. When working on uneven ground or slopes, the digger must be so positioned as to thrust the machine as little as possible. Operators can perform the task in a safer way while still increasing the level of the organization’s efficiency by strictly following these safety procedures.

Maximizing Fuel Efficiency for Cost Savings

Just like it is for consumers of light vehicles, fuel efficiency has become a noteworthy challenge for operators of heavy machinery when the price of diesel is on the upward trend.

The 2 ton digger is one that could eat up a lot of fuel if not handled in a fuel-efficient way. An efficient step towards fuel saving will be to schedule tasks in such a way as to avert walkaround activities leading to fuel wastage. To cite an example, you can stitch together similar tasks for easy movement and thus saving time as well as fuel.

Besides operators have to be very careful in the choice of their digging methods. The slow and controlled motion of digging is a very good saving technique when compared to aggressive digging that calls for more power and more fuel.

The use of power setting is just one of many ways to help you save fuel; some new excavators are even fitted with the eco-mode options that allow you to get the most out of the engine while cutting down fuel consumption. Regular preventive measures are equally important; a well-maintained engine will, over time, become more fuel-efficient and will use less fuel.

Utilizing Advanced Technology for Precision and Accuracy

As part of the technological innovation process came the fabulous realization for the equipment to be able to hold the task as effortlessly as an operator would desire. The use of GPS and top-notch hydraulically operated controls has been steadily transforming the way operators work their 2 ton machines for more precise results.

One good example of such GPS technology is that it leads operators to map out accurate excavation sites thus making sure they dig to the spec without leaving waste of the material.

In addition to that, it is possible that some models are equipped with telematics systems which offer machines’ operational data (e.g., fuel consumption, operating hours, and maintenance efforts) in real-time.

Project managers can utilize such information to plan carefully for the use of their machines and come up with a schedule where the machines will be serviced hence avoiding downtime. By these means, they will not only accomplish the task with great precision, but they will also elevate their overall working capacity.

Time-Saving Techniques for Increased Productivity

It is often said that time is money in construction and landscaping that are very dynamic markets. Hence, the use of time-saving measures when working with a 2 ton digger will let you enjoy your work in the long run.

A good example of multi-tasking is working with a machine that allows you to dig and transport the soil simultaneously. Imagine you dig a trench and at the same time use a bucket to scoop out the loosed soil; wouldn’t you say both jobs have been done in a fraction of the time? Also, another method to save time would be proper site preparation before working with the digger.

The process of removing tree stumps and old pavements from the site as well as repositioning the little material left in the area can have a considerable impact on operations.

Furthermore, it is worth noting that machine usage efficiency can be supported by operator training which will be a way to cut on idling; an experienced team will use the shortest time possible to do their tasks and still produce quality output. When these methods are adopted, one not only realizes an increase in productivity but also experiences project timelines moving smoothly.

Training and Certification for Operator Proficiency

The necessity of training and the subsequent certification is the main point that should always be brought up in discussions of heavy machinery work, less so a 2-ton digger is the case. The truth is, in addition to the safety and efficiency part, the operators are also required to know the equipment through proper training.

A lot of organizations run a certification program that is based on the core topics of machine operation, safety protocols, and maintenance practices. These programs in general provide the theory part of learning and also offer the opportunity of hands-on training, where the practical skills might be gained under the supervision of some experienced instructors.

This method, in essence, gives new operators an opportunity to familiarize themselves with the equipment and at the same time it is a great option to ensure all the good practices of the experienced professionals are more deeply ingrained. Moreover, employers are always on the lookout for certified operators as they signify the operator’s readiness for the safety part of the job and that he/she has the necessary skills.

What is more, choosing the training route is the best way to enhance one’s skills leading to more efficiency and also a safer working environment at the construction site.