A 3 ton digger often known as a mini excavator is a multi-purpose heavy machinery commonly seen in construction works, gardening, and other earth training these machines are designed to do just about every job any human being can think of, to dig trenches, and even to lift heavy materials.

By “3 ton” is meant the solid operating weight of the digger, which is usually from 2.5 to 3.5 tons. This weight category makes them a perfect tool for A 3 ton digger is made up of a rotating cab, a boom arm, and a bucket and any of them can be replaced or modified with different attachments depending on the hydraulic system is the heart of the construction, which gives the operator a certain degree of accuracy and control over the machine’s moves

The digger can be lifted and lowered as easy as one wants by the operators and this makes it perfect for tasks such as digging foundations, landscaping, It would be greatly beneficial to anyone trying to make good use of this equipment if he/she understood the major component and functions of a 3 ton

Key Takeaways

- Understanding the basics of a 3 ton digger:

- Know the weight and size of the digger

- Understand the engine power and digging depth

- Familiarize yourself with the controls and operation

Choosing the right attachments for your digger:

- Think about the work you are going to perform

- Analyze how compatible the attachments are with your digger

- Make sure that the attachments are good in quality and strong

- Take good care of your digger and maintain it in a good condition:

- Always check and change the engine oil and filters

- Apply grease on movable parts to avoid friction and wear

- Keep the digger in a place that is both dry and safe when you are not going to use it

- Some suggestions for the safe and efficient operation of your 3 ton digger:

- Do not forget to wear the necessary safety gear all the time

- Operate the machine as per the instructions of the manufacturer

- Use the right methods for digging and loading

- Make the most of the time with your 3 ton digger:

- Schedule your tasks and employ the appropriate attachments for the task

- Keep the digger in a good condition to run it at its best

- Employ the advanced digger methods to raise your efficiency

Choosing the Right Attachments for Your Digger

By equipping the necessary tools for your 3 ton digger, you will be able to achieve a wide range.

The selection of the correct auxiliary tools for a 3-ton excavator in the field of construction and civil works can lead to a significant increase in the machine’s.

Commonly used attachments are buckets of various sizes, augers to drill holes, hydraulic hammers to smash the concrete, and grapples to handle materials. The selection of an attachment.

Attachment choice depends largely on the particular work you are going to do. As an illustration, if digging trenches is the main job for you, then a narrow trenching bucket.

The accessories that are to be attached to your excavator should go hand-in-hand with the model of the excavator. Not all attachments fit any excavator It is also very important to invest in the manufacturing of high-quality attachments as this will bring about better performance and the longevity of the product

For example, a heavy-duty bucket made of high-strength steel could be the answer to the trouble of rugged

Proper Maintenance and Care for Your Digger

If you are the owner of a 3-ton digger, it is of great necessity that you maintain it properly in order for it to serve you a long time. Routine maintenance should be done on a regular basis and should consist of the following: Checking fluid levels (engine oil, hydraulic fluid, coolant), as well as inspecting (filters, belts) for wear and tear.

Particularly a well hydraulic system allows great success as it is the power source for most of the digger’s functions. Managers, on the other hand, should always check the condition of the hoses in the run for leakage or damage and replace the worn components immediately so that a big breakdown is not experienced during the work.

Apart from the routine checks, if the digger is cleaned after it is used, the dirt and the debris will not have access to the critical parts. This not only is good for the maintenance of the machine, but also for preventing some of the mechanical issues that may occur due to dirt clogging the filters or affecting the moving parts.

Seasonal maintenance should also not be forgotten; for example, making sure that the digger is safe for winter is more than just that, it is also a way of preventing ice formation inside the machine which can lead to serious damage.

Operators can make good use of the comprehensive maintenance schedule and be able to use their equipment to the maximum while the periods of machine downtime are kept to a minimum.

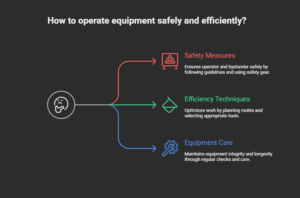

Tips for Operating Your 3 Ton Digger Safely and Efficiently

If you want to operate a 3-ton digger, the process needs to be handled by a person who is talented, educated, and that follows the set safety guidelines. Most important of all, it is a must that all checks be made to the machine when it comes to starting the work.

These checks include the brakes, the lights, and the safety features such as alarms and also the reversing camera. Moreover, apart from the general safety features of the machinery, the operators need to know the specific control features of their machines as the layout and functionalities of different models vary.

Another point that factors into the safe operation of a digging machine is the safety of the operators themselves. The use of the proper personal protective equipment (PPE), namely the hard hat, gloves, and steel-toed boots, can be a big help in the reduction of the chance of injury on the work-site.

Additionally, the workers need to be in a “look out for” position all the time. In short, this means they need to check for power lines above, co-workers working close by, and also the likely hazards within an area.

By establishing a method for remaining daily alert and following the safety codes set by the company, the operator can lessen the amount of risks and have more efficiency during the operations.

Maximizing Productivity with Your 3 Ton Digger

To maximize your 3 ton digger’s productivity, working with precision and advance planning of the tasks is a must. Planning means getting into the job site in advance and finding the best way to handle your task with less time and labor required.

For instance, one can dramatically improve the workflow just by organizing the materials and the equipment in a way that the travel time has been minimized. Similarly, the use of tools that perfectly fit a task might make the work very fast; for instance, if one were using an auger instead of the bucket for post holes, a lot of time and effort can be saved.

Besides, co-workers relations are an important factor in improvement of productivity. Good communication is all it takes to make members understand and adhere to their duties and roles, which, in no time, will lead to the prevention of the occurrence of delays and confusions during the operations. Another pro for productivity is the employment of GPS systems and machine control software in the operations.

This type of technology that can bring about productivity is the one that offers data for the depth of excavation and the right positioning. Thus, by the use of such instruments plus the implementation of the mentioned strategies, the users of 3-ton diggers will be able to fully utilize their machines and increase their work.

How to Handle Different Types of Terrain with Your Digger

Working a 3-ton digger on different ground surfaces is a challenge every time. It also requires an operator who is skillful and adaptable. For example, working on a deep and soggy ground might require tracks that are wider or special pads in order to distribute the weight more evenly and also to keep the machine from sinking.

On the other hand, if the ground is full of rocks and is uneven the only way to get through the situation is by being very cautious not to injure the machine or to cause accidents.

Hence, knowing how to change your way of doing things depending on the condition of the ground is the key to safety and even efficiency. Operators need to be very careful and use their good judgment in case they have to operate the machines on steep slopes or over sharp inclines so as to avoid accidents like the machine tipping over or losing control.

Techniques like keeping the load very low and going up the slope at an angle are some of the ways that can help the operator to maintain the stability of the machine.

Also, when conditions are such that space is very limited as in the case of working in a confined area or urban environments, operators should always be aware of their swing radius and make sure that there is enough clearance before moving the machine.

By knowing the right techniques for different terrain, the operators will not only increase their efficiency but also have the ability to lessen the impact of the risks that come with these challenging conditions.

Increasing Efficiency with Advanced Digger Techniques

Some advanced techniques can greatly increase the effectiveness of the operations by a 3-ton digger. One such technique is the use of precision grading methods which allow the operator to set the exact elevations needed without the need for wasteful rework. This is achieved by employing laser levels or even GPS technology to accurately guide the digging operations.

Basically, by making sure that every pass is done to perfection, the operators will be in a position to counter the wastage of materials as well as to save time on the next grading jobs. Mastering the ability to simultaneously perform multiple movements is another major advanced technique.

For instance, controlling the swing of the boom while at the same time raising or lowering the bucket will not only make operations smoother but it will also increase the productivity.

The training in these advanced techniques does one major good as it not only enhances the operational efficiency but also elevates the safety levels because it keeps the unnecessary movements that might lead to accidents or cause equipment damage, at bay.

Getting the Most Out of Your 3 Ton Digger Investment

A 3 ton digger is a major purchase that requires a lot of money, so as a user or business owner, it is imperative that you get the most out of this purchase. Keeping up with the technological advances in the design and the function of the excavator is one of the efficient ways to do it. The new models might be more fuel-efficient or have better hydraulic systems that will save money gradually.

Besides that, enrolling in the training programs or workshops that are concentrated on the excavator operation can be a very good investment by the skills and knowledge of the operator.

The well-trained operators are likely to operate the equipment less costly and more efficiently, as well as less safety issues, which will lead to fewer repairs and higher productivity.

Moreover, it is also good to consider other alternatives such as leasing or renting more attachments rather than buying them if your project needs so that you can have freedom without paying the full price of the equipment.

By these means, the operators can be certain that they are enjoying the highest worth of their 3 ton digger investment and at the same time improving their capabilities.