Skidsteer loaders have changed the face of the construction and landscaping industries their compact design and versatility being the main factors. At the core of skidsteer technology is a one-of-a-kind drivetrain that enables the user to achieve excellent maneuverability. Contrary to standard vehicles, skidsteers are driven independently on each wheel they thus can even rotate in a place.

The process is done by employing a hydraulic system through which each wheel is turned to a different speed thus making one able to carry out sharp turns and move swiftly in small spaces.

The feature of turning the spot makes the skidsteers the best suit for the constructions taking place in the cities where due to urbanization the spaces are normally very small. In addition to the movement role, the hydraulic system also serves as the power supply for various attachments, thus increasing the unit’s usefulness.

Skidsteer can be equipped with not only basic tools such as a bucket or a fork but also with specially designed tools for a particular job such as an auger or a grapple. The characteristic of the machine to be used for different purposes under one operator is a notable advantage as it would save the time otherwise spent on changing the machines.

By using modern hydraulic technology, the lifting capacities as well as the efficient work have been further improved thus making the current skidsteers more powerful than the old ones. A proper understanding of the technology upgrades, in fact, necessary for the operators as well as managers as the latter use this information to make decisions on the choice of equipment and job site planning.

- Deciding on the most suitable attachments for a job, skidsteer will be vital not only to the maximum output of the machine but also to the eventual saving of time and effort.

- Regular maintenance and repair of the skidsteer equipment are very important to the safety and duration of service.

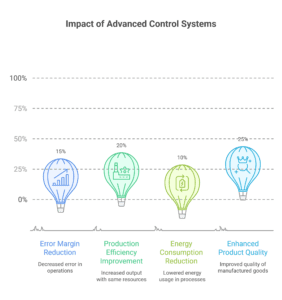

- One of the easy ways to raise the effectiveness of the management of a skid steer is to incorporate the use of advanced control systems which will lead to more precision and productivity.

- Equipping the skidsteer with telematics for remote monitoring and management can yield savings through a better utilization of the machine and proper maintenance scheduling

Choosing the Right Attachments for the Job

Using a proper and safe attachment for a skewed is a matter of extreme importance due to the fact that we would be able to maximize the productivity and at the same time, make sure that the tasks are done on time.

You can find plenty of attachments in the market. It is very easy to be lost in the sea of attachments that are suitable for the work you are planning to do. However, the better understanding of what exactly would the job require will make your decision much easier and faster.

For example, if the job you want to do is to move out soil or gravel that is too much in volume and heavy, so it is most proper then to use the bucket as your heavy-duty attachment. On the other hand, if you are involved in a task that requires exactness like grading or leveling, better you make use of a land plane or a grading scraper as the attachment for your work.

Moreover, depending on the skid steer, the attachment may have a big impact on the performance of the machine and the quality of the project done. For example, a demolition job can be taken to the next level by just one step if a hydraulic hammer attachment was in place.

This means that workers would be able to knock down concrete or asphalt very fast and with less effort. Just like that a snow blower attachment can make a skid steer snow removal machine that would be perfect for the clearing of snow in winter.

Not only the work that needs to be done but the nature of the terrain and the environmental conditions should also be taken into account when choosing the right attachments. By this kind of approach, safety and efficiency are kept at a high level which means that operators are able to handle different situations without any problem.

Proper Maintenance and Upkeep of Skidsteer Equipment

It is essential that a regular maintenance routine has to be followed in order to achieve the patience life and the great reliability of a skid steer machine. A machine that is well taken care of through its scheduled maintenance not only delivers better but also greatly lowers the risk of sudden breakdowns which can be a source of expensive downtime.

Operators have to strictly follow a routine maintenance schedule that includes the checking of fluid levels, the inspection of the hydraulic hoses for leakages, the confirmation of the filters being clean and performing well. For example, hydraulic fluid has to be changed regularly in order to avoid contamination which can lead to a great problem of the hydraulic system.

As well as the routine checks, the operators have to be on a lookout for both the condition and the wear of the tires too. Skidsteers are normally in tough places where it is very easy for the tires to get holes or wear out at a fast rate due to the nature of the place.

By regularly looking at the tires for punctures and keeping them at the right pressure will not only help you in increasing traction and stability but also will be part of the overall performance improvement.

Moreover, it is also a fact that when a skidsteer is free from dirt and other particles, that is not only the maintenance of its beautiful look but also that the prevention of corrosion and mechanical problems over time has been done. Operators who take maintenance of their machines as a top priority can be assured that their machines will always ready for work at any job site without fail.

Implementing Advanced Control Systems for Increased Precision

The development and change in control systems of skidsteer technology have been really amazing. The whole precision component is also multiplied and as well is the user experience.

The state-of-the-art electronic control systems are one of the main highlights and they allow an operator to handle the machine with ease. One example can be the joystick controls that are part of these control systems and they allow the operator to experience great sensitivity and quick response while operating the machine.

These particular features find their use when the operator needs to handle some tricky work in an area that is already crowded with other materials or work under some restricting tools.

Besides, a few sophisticated machines even come with features such as automatic leveling and tilt control, helping the operator to keep the attached part at the required angle during the whole process.

The operator’s mental effort is thus lessened by this system as they can concentrate on what is going on around them instead of constantly adjusting their tools. A further precision-enhancing measure is the adoption of GPS technology in skidsteer operations. A real-time position, as well as mapping, is what GPS can provide, thereby making the work much more efficient by the same operator.

Utilizing Telematics for Remote Monitoring and Management

Telematics has become the most influential factor in the management of skidsteer equipment as it provides real-time data useful in decision-making. With the installation of telematics systems, fleet managers are given the opportunity to track various metrics such as fuel usage, engine hours, and maintenance needs from a distance.

The adoption of a data-driven mentality towards taking decisions concerning the maintenance schedule and the operator’s time is mainly responsible for the great savings that are made on the total cost of the operation.

For example, telematics can notify managers of the time at which a piece of equipment is ready for servicing or if a machine is functioning out of the set pattern. The ability to intervene and prevent problems that can be turned into huge issues becomes thus available.

Besides, the telematics system generally comes with GPS tracking facilities that can be a great help in the management of fleet logistics by revealing the locations at which the vehicles and the vehicles have been used. The information thus obtained can assist in the allotment of work on the site, ensuring that the different projects’ equipment has gotten utilized correctly.

Training and Education for Skidsteer Operators

- Training and education are necessary for ensuring the safety and efficiency on job sites when using a skid steer, thus it is greatly needed. The proper training programs provide the necessary skills to the operators so they can handle the machine safely as well as are aware of its capabilities and limitations.

- The training must be complete in not only the way the machine should be used but also in safety, maintenance, and emergency habits. For instance, the operators need to be trained in identifying the possible dangers on job sites and in ways to risk prevention through the use of the heavy machinery.

- In addition to this, continuous education is critical as the technology sector in the industry keeps on changing. The learning of the new features and the usage of the new attachments should be up to date.

- Certification programs presented by the manufacturers of the equipment, are meant to give operators hands-on experience with their specific equipment and therefore they are fully aware of the machines’ functionalities.

- By placing a high value on training and education, companies can initiate a culture where the safety and the competence of the workers, as a result, can lead to increased productivity and lowered accident rates, will predominate.

Optimizing Workflows and Job Site Layout for Efficiency

The organization of a work site is essential in determining the workflow efficiency while using skidsteers. A well-arranged site gets rid of all the unnecessary movements and increases productivity by placing materials, equipment, and access points at the right locations.

So, by putting the materials in the areas where they will be used close by will reduce the travel time for the operators, thus, they can do the tasks in less time. Furthermore, the areas which the vehicles will take to pass through should be well defined to allow the smooth movement of vehicles from one area to another. The introduction of the different zones for the specific activities can also bring more efficiency.

For instance, the existence of different locations for loading materials and for digging works can slow down neither the one nor the other. Equipment using signs or colors can be used to help the operators navigate their way through complicated job sites, thus, there would be minimal confusion and the safety is also enhanced.

Project managers will by putting customer job site layout planning into action be able to create an environment in which they are able to use the skidsteer in an efficient manner.

Incorporating Automation and Robotics for Streamlined Operations

The adaptation of automation and robotics into skidsteer functionalities marks a great leap in construction tech. Systems that are automated can significantly improve the efficiency of operation by simply executing the same routine tasks that they otherwise would require human intervention every time.

A case in point is the automated grading systems which can command blade angles according to the relief of the land in real time thus getting the same results without any manual interference.

It is evident that along with time-saving, operator fatigue during extended hours is also alleviated. Besides that, robotics can be merged with skidsteers to do multi-faced jobs with extreme accuracy.

An illustration of the same is the robotic arms fitted with the necessary equipment that can function as a skidsteer counterpart when it comes to handling fragile goods or doing complicated commissioning right on the spot. Such partnership between human laborers and mechanical aids ensures there are still numerous ways to conduct the operations.

The quality is also kept at a high level under such safety measures. Nevertheless, the progression of science will most probably open more avenues for the application of automation in skidsteer operations, resulting in the development of even more efficient construction processes in the future.