Compact excavators are multi-purpose vehicles that can handle various jobs in construction and landscaping. In general, these devices are defined by their small-sized, usually ranging from 1 to 10 tons, which gives them the ability to work in small spaces where large excavators are not allowed. Their layout comprises a rotating house, a boom, a dipper arm, and a bucket, which in turn makes them to exact and effective cleaning, grading, or lifting work.

Just as the size of these machines is suitable for the downtown construction projects, the yards and utilities works also can fit well with these mini excavators. The variety of compact excavators is made even better by their capacity to carry almost any accessory. From the hydraulic thumbs to the augers and the trenchers, these attachments can make the operators transform the machine into one that can perform a task set forth, thereby, increasing the machine’s utility in a various field of application.

Secretly, an excavator combined with a hydraulic breaker can be used for the demolition of concrete structures in a quick and easy way, whereas a machine fitted with a bucket can turn to the earthmoving side of the task. Such versatility not only ensures that the function of the machine is at its highest but also provides huge savings to the contractors who get the chance to do more than one job with a single piece of equipment.

Key Takeaways

- Compact excavators are versatile machines that can be used for a variety of tasks in construction and landscaping.

- To start with, the safest, easiest, and most efficient way of digging is to use a compact excavator with the right attachments for your machine and the task.

- Keeping a compact excavator functionally sound and always performing at the best level it can, is very achievable through good maintenance.

- Operator training and safety should be always at the top of the list of priorities because if an accident occurs, the loss and damage will be costly and dangerous.

- A smart technology like the GPS and telecommunication system is at disposal to help the energy saving and the accuracy of the operations of the compact excavators.

Choosing the Right Attachments

The first step to get a better performance, and even to meet the specific demands of a project, will be the proper selection of the right attachments for a compact excavator. Any of the programs in which the machine is used can be more effectively carried out by simply choosing the correct attachments.

As an illustration, digging with a standard bucket in a situation where there is a need to handle forest and hard soil the operator may decide to make use of a heavy-duty bucket so as to resist the difficult conditions.

At the same time, a grading bucket will be like a charm to you, achieving the very nice finish of the soil or gravel surface for the landscaping work, thus making it look more beautiful and attractive.

In addition to the common usage of buckets, there is a continuous challenge of discovering new ways and comes with the good news is that there is an increasing number of exclusive compact excavator attachments to overcome these problems and find more applications of compact excavators in different segments of the economy.

The implementation of a hydraulic thumb is not only for facilitating the grasping of materials that are irregularly shaped but also for allowing the operator to have better control over the machine while doing so.

So, if the project you are working on requires you to do very accurate digging, then an auger will be good for you, in which case the operator will be able to open holes for the fence posts or plant trees in no time and exactly where the spots are.

In addition, the attachments like tilt buckets increase the capability of the grade work with more precision and flexibility as the process of obtaining the desired slopes and contours by operators working without frequently relocating the machine is possible with the help of them.

Proper Maintenance and Care

Compact excavator maintenance is a must if the machine is to be kept in good shape throughout its whole lifecycle and during off-peak performance. Daily maintenance schedules should include a check of the machine’s fluid levels, hydraulic systems, as well as tracks and undercarriage components for wear.

The operator should always follow the guidelines set by the manufacturer, which basically means the part changes will involve engine oil and filters, belts and hoses will be inspected and lubricating parts will be done.

On top of that, missed maintenance tasks will gradually result in the machine breaking down and will bring long unproductive periods leading to lost time and profits. Besides regular maintenance, the operator through the daily pre-operation check must ensure everything is in place before using the machine.

It includes looking for any visible damage, confirming that safety devices are working properly, and all the controls are functioning. A compact excavator must be a dust-free and clean machine as well.

Dirt and debris will find their way into crucial areas which will cause them to overheat or even fail mechanically. A company can go a long way in saving itself from sudden breakdowns by the adoption of maintenance programs and the creation of a culture of care among its staff.

Operator Training and Safety

One of the contributing factors to accidences is imprudent compact excavators operation thus safety should be a priority in such kind of working environment along with the good productivity obtained as a result of safety practice.

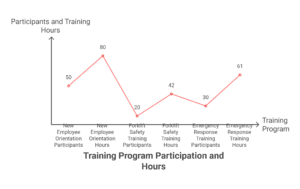

A properly trained operator will have no problem in understanding the machine’s control system, possible uses and limits of the machine. The competence of operators in executing the machinery trainings will be very significantly proficient regarding not only the technical side of the machine but also the safety issues addressed in the respective training.

This may include the understanding of the terrain and nature of the hazard such as the presence of electric lines or if the ground is unstable and at the same time implementing the correct way of utilizing personal protective equipment (PPE).

Constantly holding training sessions, is also a kind of refreshment, which provides an opportunity to keep the knowledge of the operators up-to-date with the latest industry trend and the new technology in the field. With the growth of technology, the addition of complex features such as GPS guidance and telematics have been introduced in compact excavators.

So, in order to keep track of these developments, the operators must be equipped with the necessary knowledge and skills. Alongside safety drills and periodic refresher courses, safety operating standards and virtues would be deeply ingrained within the organization’s culture.

A company which is committed in providing its operators with all the necessary training and resources will not only be able to promote safety in the workplace but will also be able to raise overall productivity of the company by ensuring that the operators are highly skilled and confident in operating the machines.

Utilizing Advanced Technology

The power of technology to elevate the performance of compact excavators has made a revolutionary change in the way machines are operated on job-sites. Just imagine what a telematics system can do- it gives real-time information on the performance, location, and maintenance needs of the machine.

Using this information, fleet managers could easily keep a close eye on the equipment consumption, prepare maintenance on time, and thus, minimize the chances of labor hours resulting from sudden malfunctions.

Moreover, to give you an example, when a telematics unit signals that the working conditions of a machine are not within the expected range, the managers will not only help the machine but also workers heal with their timely maintenance and replacement plans.

The progress and the experiments that are the backbone of the revolution in maneuver compact excavator movement are now also in automation as the recent announcement of numerous protocols indicates.

Some units are now equipped with such features as automatic grade control or integrated GPS systems that enable operators to get the accurate depth of the ground without the necessity of constant manual adjustments.

In addition to that, these technologies facilitate operators in various ways by increasing the precision of their tasks and lessening the abrasion due to the performance of the same routine activities. Finally, mas and power tools will continue to industrialize and sophisticated their commitments gradually in the foreseeable time frame, and adopting these developments will be a determining factor in a company’s survival in highly competitive and demanding markets.

Planning and Organizing Work Sites

The modus operandi for productive planning and successful organization of work sites largely determines the vice of project implementation when dealing with powered road tools.

Thus, site assessments ought to be performed even before digging any hole, not only identifying potential challenges such as underground utilities, but also paying attention to environmental part of the project. This pre-planning stage gives the project managers the opportunity to think through the problems that will not only create chaos but also block the efficient flow of the project.

For instance, areas such as where to keep materials and/or where to stage the equipment, can be mopped and dedicated strictly for these purposes to make the operations run smoothly being the source for the avoidance of the unnecessary movements that may revolve around the work site.

Apart from that, work site organizing means trades coordinating and ensuring that all the team members are fully aware of their job descriptions and duties. There is no doubt that members of the crew have to be in good rapport and communication among themselves, not only to maintain high safety standards but to ensure efficiency as well.

By using visual tools such as the site plans painters often employ or a digital project management software, they may monitor progress and find out about modifications all the time.

Goths in three influential areas, namely, company – workers – workflow model in which jobs tasks are defined unambiguously and resources are effectively allocated, allowing companies to increase productivity and at the same time cut back on time lost by communication and logistical mistakes.

Optimizing Fuel Efficiency

- The rising fuel prices and environmental issues are the factors that lead fuel consumption into the yes list of the problems to be solved by the operators of compact excavators. In order to make the consumption of fuel be optimized by the operators, they need to follow the best practices that will help the machine run in an efficient way.

- An effective method is to limit the time when the machine is idling; the stoppage of the engine when the machine is not used can save a lot of fuel over time.

- Moreover, the operators have to be qualified in the smooth working methods to be able to do the work with gradual rather than abrupt and wasting movements which are fuel-consuming.

- The maintenance of the excavator’s engine and hydraulic systems is yet another factor affecting fuel efficiency. The full air filters and some lubricants running smoothly in the injectors enabled that the burning process would be efficient and fuel consumption would decrease accordingly.

- Apart from that, the use of telematics can be a great help in understanding and so interpreting the fuel patterns of usage which can make detection of improving areas easier for the fleet managers. The focus on fuel not only necessarily leads to the period of less seasonal costs but is also a part of the overall sustainability scheme of the construction industry.

Maximizing Productivity and Profitability

Productivity of compact excavators can be maximized when the company pays full attention to their working potential, thus the need for downtime and operational costs will be reduced.

One method of achieving this is to create a planning and systematic scheduling process that will be in line with the availability of the equipment and the time frames of the projects.

Taking advantage of the machines to the fullest extent possible, not only in one project and systematically, but also in the subsequent works of the stage or in the interim periods can lead to a rise in productivity of the company.

Besides that, the use of well-trained and experienced personnel is a step in the right direction as the correct and efficient use of the tools will enable them to finish their task much faster.

Profit is directly related to productivity; hence, companies are supposed to use the benefits they get from the increased productivity and to identify cost cuttings that can affect the bottom line positively.

The method involves being very keen on the analysis of project budgets in order to utterly find where the money can be saved without affecting the practice of good quality and safety.

Even though use performances and equipment may result in higher upfront costs, the investment will, however, lead to major savings if the company chooses to go down the route of efficiency and labor cost reduction. Companies may experience sustainable growth as they move through the increasingly challenging competitive environment by implementing the holistic strategy that combines resource utilization skills with labor management as well as the prudent use of capital.